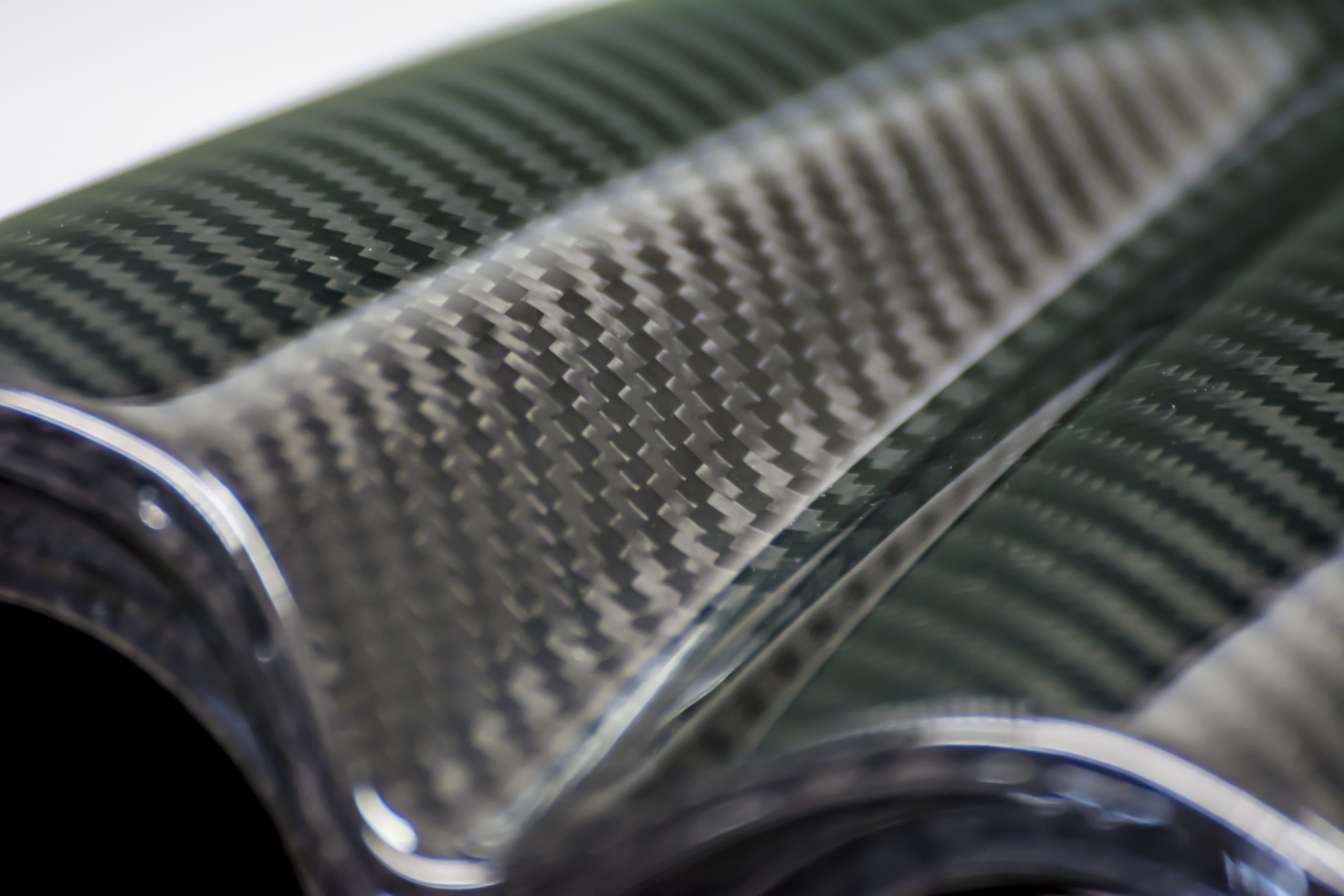

JOTA Composites specialise in manufacturing autoclave cured, complex components in a wide range of materials including carbon, aramids and sustainable materials.

JOTA Advanced Engineering specialise in manufacturing fully inspected, complex components in a wide range of materials including aluminium, stainless steel, special alloys and plastics.

We offer full project management for the manufacture of components, with our team of experts overseeing the process from start to finish, enabling us to deliver an accurate on time, on budget product.

A turnkey service

Services we provide include DFM, pattern, mould, component design, manufacture and assembly.

We utilise our extensive network of approved sub-contractors to offer further specialist solutions, including pattern manufacture, FEA, paint and lacquer.

Key personnel

The core team driving the innovations at Jota Composites.

Matt Cox

DIRECTOR

Matt has been at the forefront of the composite industry since he began his career 30 years ago. Having successfully transitioned from manufacturing and engineering to business leader within 5 years. He has started and developed companies, with an appetite for breaking the mould of traditional business and manufacturing models. Having experience with OEMs in all sectors requiring composite products, he is able to direct all aspects of the process at the highest level.

Samantha Littler

DIRECTOR

Sam has flourished in her 15-year career in the advanced engineering sector gaining invaluable experience in commercial, programme and operational roles. Having been senior management and director level has managed workforce, customer base and installation of distribution networks she is very experienced within the composite sector. Sam also possess the ability to direct all elements of the business and harness a great management style.

Experts in our fields

The management experience has delivered on hundreds of high-profile projects from prototyping to niche volume production. Some examples include.

Defence

Foxhound military vehicle from concept to reality. Urgent operational requirements (UOR) for ‘lightening the load’.

Sporting

Le Mans, GT racing and F1 programmes. Super bikes and Olympic equipment.

Automotive

Customer track cars, hyper cars and high-end niche vehicle builds.

Marine

Race winch and pedestal gear, tender hulls, super yacht trim and finishers.

Aerospace

Tooling, prototyping and flying parts. First class seating and galleys.

Bespoke

Land speed vehicles, designer furniture and musical instruments.